PILATUS Project

About PILATUS

Photovoltaic (PV) power generation is pivotal in the transition to a clean energy system and the achievement of the zero-emissions target. In Europe alone, installed PV capacity is expected to reach 8.8 TW by 2035. To succeed in the competitive global market, the EU PV manufacturing industry needs to focus on high-performance PV technologies, such as high module efficiency and high energy yield in kWh, which reduce the Levelized Cost of Electricity (LCOE) of PV in all applications. Additionally, the Product Environmental Footprint, including durability, recyclability, and circularity is becoming a particularly important selection criterion for PV in the EU.

In that light, PILATUS is a 3-year project aiming to demonstrate three digitalised pilot lines for the production in Europe of silicon wafers, solar cells, and solar modules. PILATUS will contribute to re-building a “made in Europe”, leading-edge, competitive PV industry with the entire value chain retained in Europe and compliant with the latest environmental standards.

Objectives

Develop and demonstrate the high-volume production of high-efficiency silicon Heterojunction (SHJ) tunnel-Interdigitated Back Contact (tunnel-IBC) solar cells and modules in pilot-lines equipped with high-level automation.

Develop the industrial tools, processes and materials for the SHJ tunnel-IBC pilot lines thereby strengthening the European PV knowledge base and supply chain.

Demonstrate good traceability from wafer level to PV module’s field installation combined with the automation and feedback loops to pilot lines.

Validate the performance of the PV cells and modules from the SHJ tunnel-IBC pilot lines.

Eco-design of tunnel-IBC PV modules and manufacturing lines toward zero-waste via life-cycle assessments and developing optimisation roadmaps.

Document and pre-certify the PV cell and module performance to ensure replicability and further scalability of the production capacity.

Demonstrate favourable cost/Wp of the SHJ-IBC modules compared to state-of-the-art commercially available PV modules and proof the potential of business cases towards special product applications.

Concept

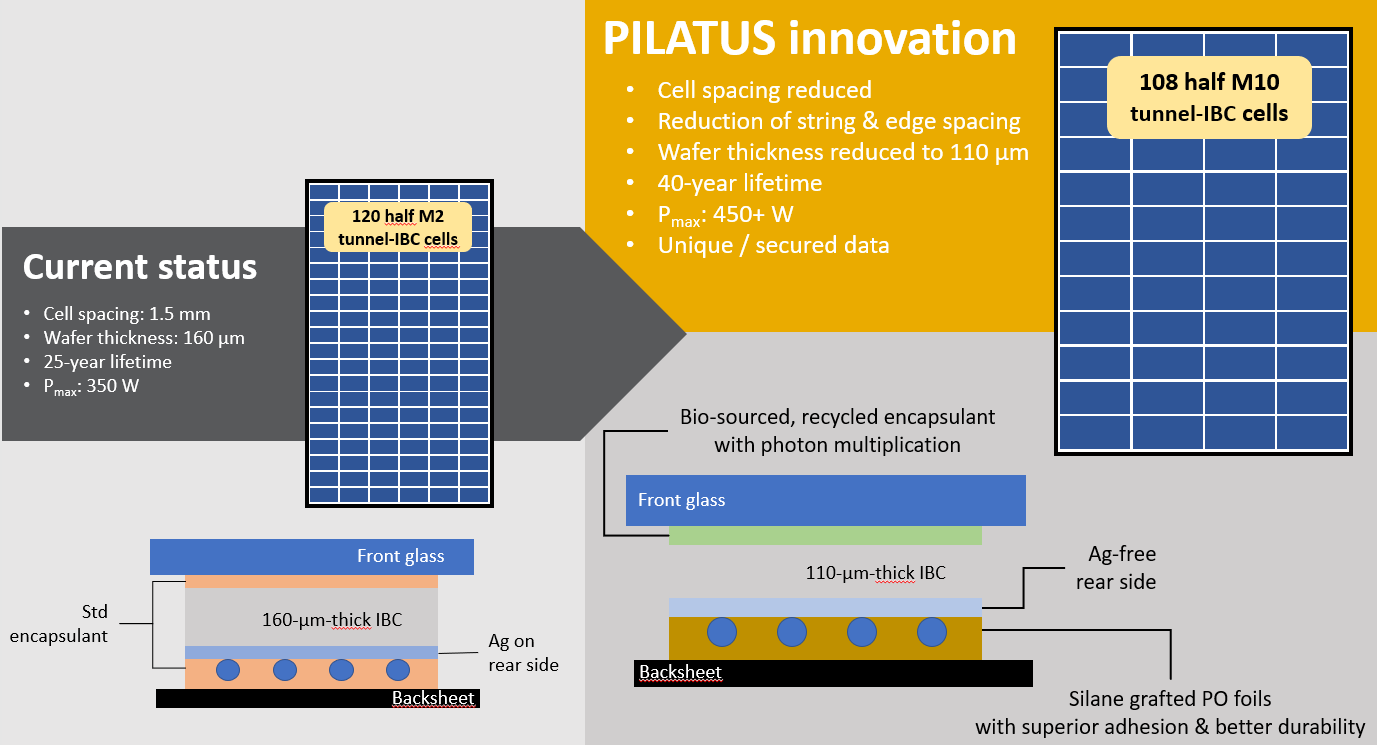

The PILATUS project aims to scale up the production of the next-generation tunnel-IBC cells and modules that combine the silicon heterojunction (SHJ) technology together with the interdigitated back-contacted (IBC) architecture in a simple manner.

The project will be able to demonstrate the outcome at pilot line using the ‘best in class’/State-of-Art solution, but – at the same time – will work in parallel on specific technological aspects which still have significant room for improvement (see figure below). This may offer even higher performance, lower costs, and increased versatility of the PILATUS solution.

Approach

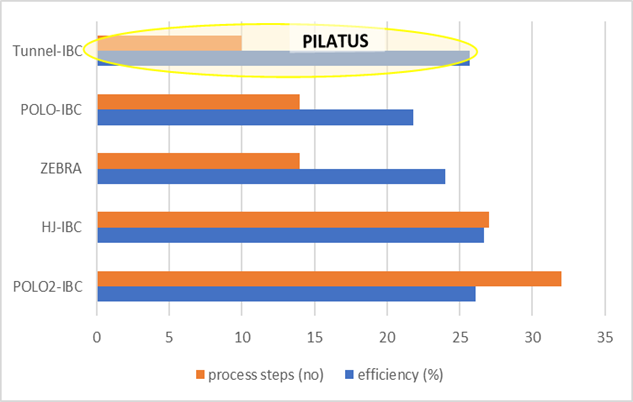

The SHJ-tunnel-IBC technology that will be used in the development and demonstration of the PILATUS pilot lines has clear advantages over other IBC technologies. The figure below shows the number of process steps to produce various IBC cells. Producing tunnel-IBC cells requires only 10 process steps, while most industrial IBC production need many more steps, (i.e. higher production line investment costs). At the same time, tunnel-IBC leads to 25.5 % cell efficiencies, thereby outcompeting ZEBRA and POLO-IBC. Overall, tunnel-IBC industrialisation would lead to competitive pricing in the premium PV product category with competitive average cell efficiencies.

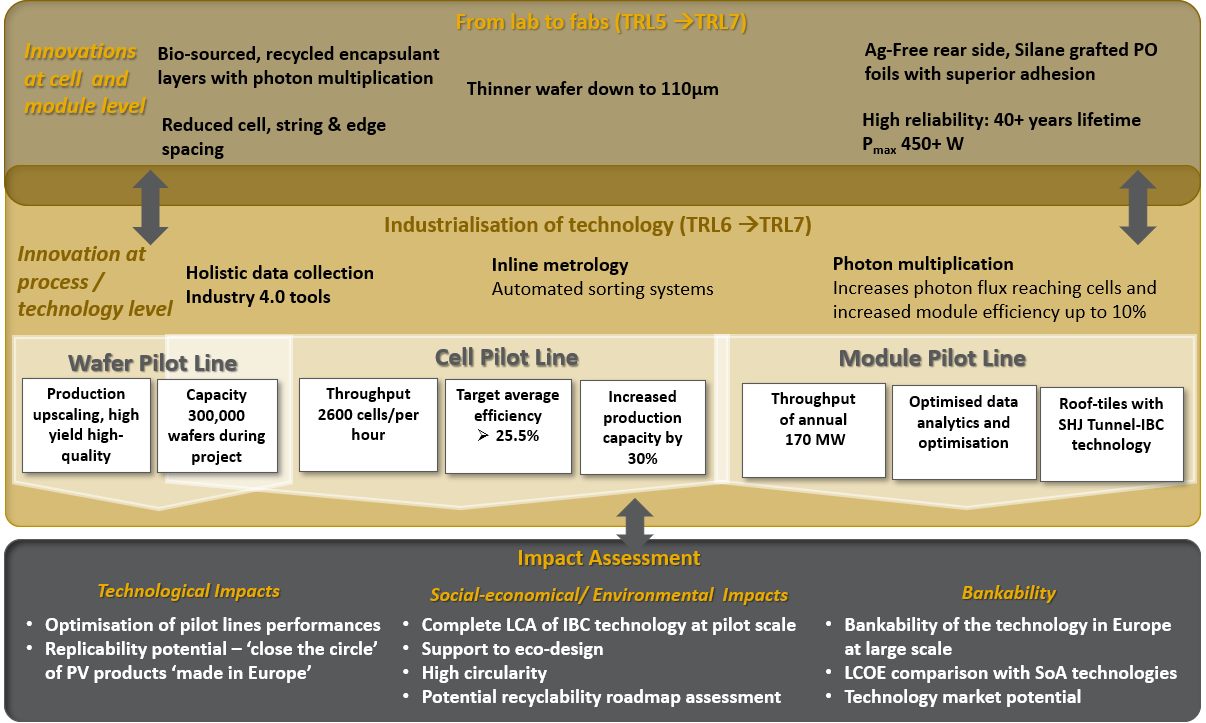

The next figure presents the project methodology covering the main aspects of the SHJ tunnel-IBC value chain, from lab scale technological optimisation to new system development, automation, data analytics and optimisation, demonstration of new cell and pilot line including the impact analysis (techno-economical, sociological, and economical aspects).

Results

PILATUS aims for:

- a production capacity of 15 MW for M10 silicon wafers in Norway using polysilicon from Europe and demonstrate the feasibility of an expansion to 5 GW wafer production capacity.

- A PV module pilot line that will reach a minimum of 170 MW of annual production capacity, accompanied with 190 MW cell capacity that by itself adds 30% to the current total capacity for PV cell production in Europe.

- combining inline metrology and outdoor monitoring with the support of Industry 4.0 concepts all along the production chain, the cells and modules fabricated on PILATUS’ pilot lines. The metrology and monitoring will be analysed and feedback provided to the manufacturing process to ensure reaching ≥ 90% yield at the end of the project.

- With the goal to establish PV modules with high durability, PILATUS targets to demonstrate the way towards >40 years product lifetime by gaining fundamental insights into the degradation mechanisms and providing mitigation solutions thanks to the inline and outdoor metrology units that will be developed in the scope of the project.

Further, PILATUS will prove a reduced environmental footprint compared to current technologies by demonstrating modules fully made from recycled materials, eco-design practices to facilitate the dismantling of PV panels, and manufacturing plants compliant with environmental standards.

Publications

PILATUS is conducting research in the field of photovoltaic cells and modules, and will disseminate scientific results to peers in the field by means of scientific publications. All relevant publications will be posted on this page.