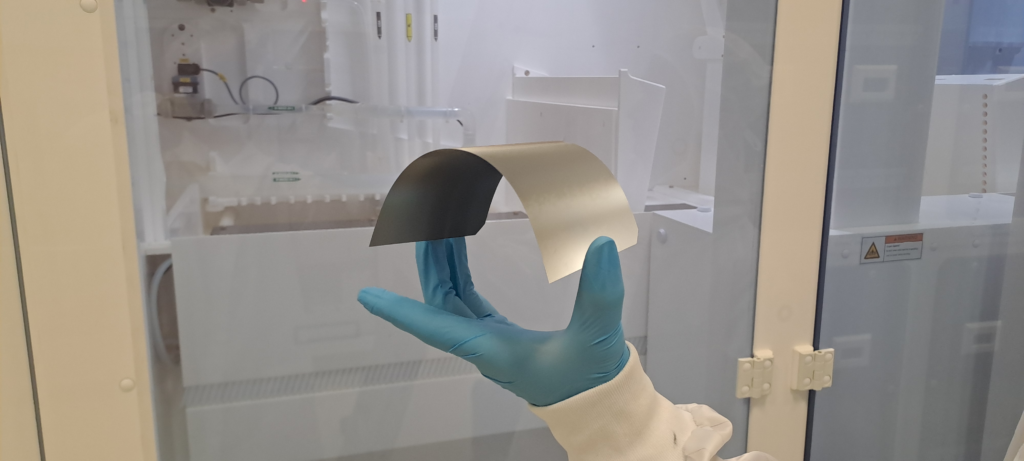

The high quality of texturing and cleaning from this tool enabled to produce high quality and reproducible wafer preparation, triggering immediately a boost in passivation quality. The first half G12R rectangular wafers were also successfully tested down to 80um in thickness. Beside the process activities, a strong effort was made at Meyer Burger Research to establish a new data base system, enabling to collect the whole dataset of each experiment for all tools installed in the cleanroom. The engineers can now analyze a huge amount of data, which are processed almost in real time, including picture analysis for all experiment started. This initiated a lot of discussions around the power loss analysis and how to adapt the processes to boost further the efficiency and reaching one of the Pilatus’s objectives (25.5%). This level of efficiency positions this technology near the forefront of the PV industry and the team is really confident to reach it soon.